Commercial Facility Water Customers

Cross-Connection and Backflow FAQ

FAQs

PART I: INSPECTIONS / SURVEYS

Yes. The Regulation became effective on February 11th, 2021. It requires each local public water system implement a program to educate, assess services for potential cross-connections, cause corrective actions and enforce state and local rules to ensure safe drinking water.

View the full regulation here: Link "New DE CCC Regulation" to this PDF: https://hydrocorpinc.com/wp-content/uploads/2021/02/Delaware-Regulation-808.21-CCC-Program-Requirments-effective-2.5.21-WORD.doc-With-callouts.pdf

HydroCorp has been contracted by the City/Village/Township to assist with their Cross-connection Control (CCC) Program. The CCC program includes two parts: On site inspections and testing of backflow prevention assemblies. The HydroCorp inspector will be conducting a visual inspection of the water uses outside of your facility (outside spigots, lawn irrigation system, secondary sources of water, pools, etc.) to identify cross-connections that could possibly contaminate your drinking water or the public water supply. If your water provider requires an inspector to enter your facilty to evaluate other cross-connection and plumbing hazards inside your residence, you will be notified and instructed to schedule an appointment for your inspection.

Residential Cross-Connection Control Survey | Exterior from HydroCorp on Vimeo.

The City/Village/Township has had a CCC program for a number of years, which began with inspections of all of the commercial and industrial accounts. As a natural progression of our program we are now inspecting residential customers as required by the State.

All water customers (residential and nonresidential) connected to the public water supply are required to be inspected for cross-connections. Most programs strive to ensure that all water customers receive an initial inspection during their first 3-5 years of program implementation.

An average inspection normally takes from 10 to 20 minutes, depending on the size of your facility/property.

Interior Inspections: YES – if you received a letter informing you to call and arrange for an appointment, someone over 18 must be facility to allow our inspector to enter the facility and complete the inspection.

Exterior Inspections: NO – if the inspection is for the exterior of your facility only, HydroCorp will not be entering your facility and they will only require access to your front and backyard. Some states and local jurisdictions allow for a mail/electronic water use survey to be completed by the owner.

Yes. We just need a name and number so that the inspector can contact you to set up a time that is convenient for you.

If you are the owner of the facility being inspected, you are responsible for any needed repairs. Renters may have to refer to their lease agreements in order to determine whether they are responsible for repairs.

All HydroCorp inspectors wear photo ID badges during inspections and are prepared to provide appropriate documentation verifying their identities.

Yes. These inspections are conducted in order to ensure compliance with state regulations to maintain the safety of your drinking water.

Penalties for refusing to cooperate with inspections and/or refusing to make needed repairs are determined by your local water utility. These typically can include termination of water service, a fine, or both.

There are two components of a cross-connection control program: Testing of backflow prevention assemblies and onsite inspections. It is the responsibility of the assembly’s owner to have backflow prevention assemblies tested periodically by a certified tester. Your local water supplier is responsible for the inspection portion of the program. The inspection is to verify that the proper backflow prevention methods are in place to maintain drinking water safety.

PART II: BACKFLOW PREVENTION ASSEMBLY TESTING

Just like any other mechanical device, backflow prevention assemblies are prone to wear and tear, and do break down from time to time. Regular testing is required in order to ensure that your device remains in proper working order.

(Varies by state and local authority)

It is recommended that all testable backflow preventers are tested annually, however The City/Village/Township may require less frequent testing on residential lawn irrigation systems. (Consult your local Cross-Connection Control ordinance.) If you are injecting chemicals into your lawn irrigation system, most state regulations and plumbing codes require the backflow preventer to be tested on an annual basis.

In most jurisdictions, a lawn irrigation system is not a required component of the water system. Facility owners who choose to install a lawn irrigation system as a convenience are responsible to assure the backflow preventer is properly installed and maintained in accordance with State laws and regulations. It would be unfair for the City/Village/Township to require facility owners who choose not to have a lawn irrigation system to absorb the financial burden of maintaining your privately owned system.

There are two parts to the Cross-connection Control Program. The first is an on site inspection by a cross-connection control inspector to ensure that the proper backflow prevention devices and assemblies are in place to protect your drinking water. Some of the assemblies the inspector finds or asks you to install are testable assemblies, which are mechanical and can malfunction. The testing notice refers to testing the operation of these backflow prevention assemblies. These tests must be performed by a certified tester.

“Grandfathering” is not typically permitted due to the high importance of maintaining drinking water safety. Just like any other mechanical device, backflow prevention assemblies are prone to wear and tear, and do break down from time to time. Regular testing is required in order to ensure that your device remains in proper working order.

PART III: GENERAL RESOURCES

The anti-siphon fill valve device is located in the tank of your toilet. This device has a dual purpose: To fill the toilet and prevent backflow. This device must be placed at the proper height in order to insure that water from your toilet does not backflow into your drinking water. Proper placement is typically done during the installation process but can be easily overlooked. This device must be raised or the overflow pipe must be cut down in order to achieve a 1” air gap separation between the “critical level” of the assembly.

Click here to see an installation diagram.

Click here for 3 minute video overview.

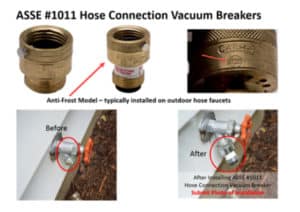

Example: Hose connection vacuum breakers |  Example: Integrated vacuum breaker on outside hose spigot. |

Example: Hose end in bucket |  Example: Hose end in pool |

|

Vacuum breaker should not be subject to continuous pressure like the example here illustrates. (This type of irrigation set up/system would need to be corrected.) |

These require periodic performance testing by a Certified Tester.

Pressure Vacuum Breaker Assembly |  Reduced Pressure Principle Backflow Prevention Assembly |

5700 Crooks Road, Suite 100

Troy, MI 48098

(844) 493-7641

Connect with us

Protecting Water. Protecting People. Expert Services for Safeguarding Drinking Water.

Website & SEO By: MI Digital Solution | Privacy Policy | Terms of Service