Cross-Connection Control Program

Cross-Connection Control Program Overview

Your local water provider is making improvements to protect the safety of drinking water. Here’s why.

A cross-connection is an actual or potential connection between the safe drinking water (potable) supply, and a source of contamination or pollution. Cross-connections can result in a hazardous event known as backflow, which can draw those contaminants into your drinking water supply.

Delaware’s Department of Health Code 4462 prohibits hazardous interconnections to public water systems and requires all public water systems development a comprehensive Cross-Connection Control Program.

Step 2

Postal Notification

Hydrocorp sends notifications informing water customers of plumbing code requirements that backflow preventers must be tested annually. Facility Assessments/ Inspections for Cross-Connection Hazards are required as specified within the local CCC plan. Instructions and due dates are included in notifications.

Step 1

Hydrocorp Assistance

Hydrocorp hired by local water purveyor to assist with mandatory Cross-Connection Control Program (CCC).

Step 3

Onsite Inspection/Survey

Water Customer selects and hires an ASSE approved Backflow Preventer Tester and/or Cross-Connection Inspector. Test and Inspection data are submitted online to the local water purveyor/utility.

Step 4

Data/Corrective Action

If cross-connections are identified during the inspection, the water customer is provided written instructions for modifications and a mandatory compliance date.

Step 5

Compliance Verification

Annual Backflow preventer test and inspection records confirmed and maintained by the local water purveyor as required by law

Step 1

Hydrocorp Assistance

Hydrocorp hired by local water purveyor to assist with mandatory Cross-Connection Control Program (CCC).

Step 2

Postal Notification

Hydrocorp sends notifications informing water customers of plumbing code requirements that backflow preventers must be tested annually. Facility Assessments/ Inspections for Cross-Connection Hazards are required as specified within the local CCC plan. Instructions and due dates are included in notifications.

Step 3

Onsite Inspection/Survey

Water Customer selects and hires an ASSE approved Backflow Preventer Tester and/or Cross-Connection Inspector. Test and Inspection data are submitted online to the local water purveyor/utility.

Step 4

Data/Corrective Action

If corrective action is identified during the facility Cross-Connection Inspection, the water customer is provided written instructions and a mandatory compliance date.

Step 5

Compliance Verification

Annual Backflow preventer test and inspection records confirmed and maintained by the local water purveyor as required by law

RESIDENTIAL WATER CUSTOMERS

Cross-Connection and Backflow FAQ

PART I: INSPECTIONS / SURVEYS

You can view it here.

A cross-connection is an actual or potential connection between the safe drinking water (potable) supply and a source of contamination or pollution. State plumbing codes require approved backflow prevention methods to be installed at every point of potable water connection and use. Cross-Connections must be properly protected or eliminated.

A public water supplier may determine that specific residential water service connections shall be inspected (with appropriate notification in advance) for

potential cross-connection hazards. Causes for residential exterior inspections are lawn irrigation systems.

A typical residential exterior cross-connection inspection takes 5-15 minutes.

No.

Building owners are responsible for costs associated with corrective action/non-compliance.

If a residential service connection owner is notified of a mandatory inspection, compliance is required. These inspections are conducted in order to ensure compliance with state regulations to maintain the safety of your drinking water.

Penalties for refusing to cooperate with inspections and/or refusing to make needed repairs are determined by your local water utility. These typically can include termination of water service, a fine, or both.

PART II: BACKFLOW PREVENTION ASSEMBLY TESTING

Just like any other mechanical device, backflow prevention assemblies are prone to wear and tear, and do break down from time to time. Regular testing is required in order to ensure that your device remains in proper working order.

Delaware Uniform Plumbing Code requires Testable Assembly Backflow Preventers shall be tested by an ASSE Certified tester at least annually and at time of initial installation. A test record for each Backflow Preventer is required to be submitted to the local public water supplier as specified in the local Cross-Connection Control Program Plan.

PART III: GENERAL RESOURCES

Residential Cross-Connection Control Survey | Exterior from HydroCorp on Vimeo.

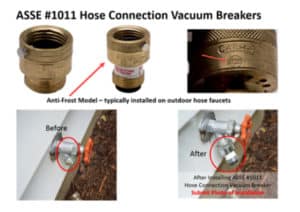

Example: Hose connection vacuum breakers |

Example: Integrated vacuum breaker on outside hose spigot. |

Example: Hose end in bucket |  Example: Hose end in pool |

|

Vacuum breaker should not be subject to continuous pressure like the example here illustrates. (This type of irrigation set up/system would need to be corrected.) |

These require periodic performance testing by a Certified Tester.

Pressure Vacuum Breaker Assembly |  Reduced Pressure Principle Backflow Prevention Assembly |

Commercial Facility Water Customers

Cross-Connection and Backflow FAQ

PART I: INSPECTIONS / SURVEYS

A cross-connection is an actual or potential connection between the safe drinking water (potable) supply and a source of contamination or pollution. State plumbing codes require approved backflow prevention methods to be installed at every point of potable water connection and use. Cross-Connections must be properly protected or eliminated.

Delaware Dept. of Health and Social Services Administrative Code 4462, section 21 states: A cross-connection control program shall include appropriate policies to complete assessments of customer premises for potential cross-connections to establish hazard criteria to classify customer premises consistent with Table 1, and to determine the degree of hazard and adequacy of existing preventive measures.

Source: https://regulations.delaware.gov/register/february2

021/final/24%20DE%20Reg%20794%2002-01-21.pdf

Residential Cross-Connection Control Survey | Exterior from HydroCorp on Vimeo.

If your building has an exterior Testable Type Backflow Preventer Assembly (ASSE 1013 or ASSE 1015 type) in supply to the interior plumbing, your inspection may take less than 15 minutes. Prior to their arrival, be sure to inform the inspector if you have an exterior or interior backflow preventer assembly. Buildings with no existing backflow preventer at the water service connection point may require a more extensive inspection.

If your building has an exterior existing backflow preventer assembly, being present may not be necessary. Consult with the inspector/tester you hire prior to their visit for final determination.

If you are the owner of the facility being inspected, you are responsible for any needed repairs. Renters may have to refer to their lease agreements in order to determine whether they are responsible for repairs.

Yes. These inspections are conducted in order to ensure compliance with state regulations to maintain the safety of your drinking water.

Penalties for refusing to cooperate with inspections and/or refusing to make needed repairs are determined by your local water utility. These typically can include termination of water service, a fine, or both.

PART II: BACKFLOW PREVENTION ASSEMBLY TESTING

Just like any other mechanical device, backflow prevention assemblies are prone to wear and tear, and do break down from time to time. Regular testing is required in order to ensure that your device remains in proper working order.

Delaware Uniform Plumbing Code requires Testable Assembly Backflow Preventers shall be tested by an ASSE Certified tester at least annually and at time of initial installation. A test record for each Backflow Preventer is required to be submitted to the local public water supplier as specified in the local Cross-Connection Control Program Plan.

PART III: GENERAL RESOURCES

Example: Hose connection vacuum breakers |  Example: Integrated vacuum breaker on outside hose spigot. |

Example: Hose end in bucket |  Example: Hose end in pool |

|

Vacuum breaker should not be subject to continuous pressure like the example here illustrates. (This type of irrigation set up/system would need to be corrected.) |

These require periodic performance testing by a Certified Tester.

Pressure Vacuum Breaker Assembly |  Reduced Pressure Principle Backflow Prevention Assembly |