An Important Community-Wide Safety Project

For years, Milford has complied with the important Regulatory Water Safety Compliance Program known as Cross-Connection Control. Until recently, this State Mandated Program focused on non-residential (commercial) water service connections.

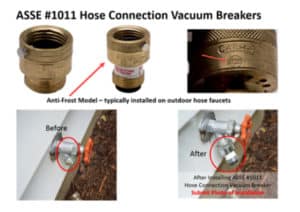

The Michigan Department of Environment, Great Lakes, and Energy (EGLE) is now requiring Public Water Systems to implement a Cross-Connection Control Program addressing Residential Water Service Connections. The brief, visual inspection of your lawn sprinkler system, boiler, or hose spigots will help shield the drinking water from potential contamination.